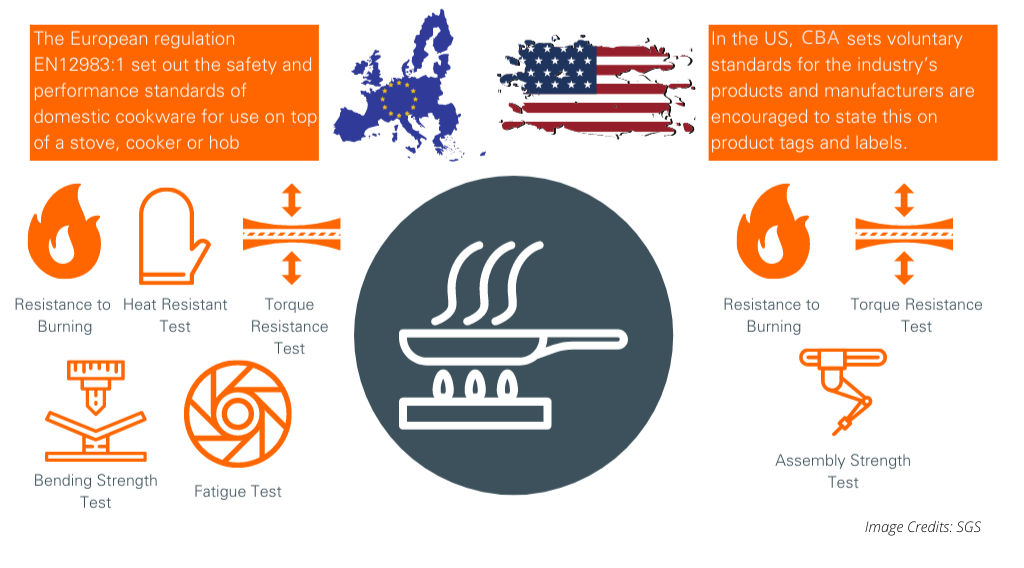

Cookware standards serve as essential benchmarks for product quality and safety. Whether you’re a manufacturer, brand owner, retailer, or consumer, choosing products that meet European regulations or U.S. standards means you’re investing in cookware that has been rigorously tested for domestic use. While these standards share common ground, they’re not identical across markets.

Have you ever wondered how cookware is tested for safety and performance? Or why it matters if your pots and pans are compliant with regional standards?

Keep reading to uncover the key aspects of cookware safety and why it should matter to your business.

EUROPEAN STANDARDS FOR COOKWARE PRODUCTS

The main European standards for cookware is the EN12983, which set out the safety and performance of domestic cookware for use on top of a stove, cooker or hob.

The EN 12983:2023 has been lastly updated and released in 2023 and it introduces significant changes to the construction and performance requirements for household goods. Understanding these changes, as well as the tests involved, is crucial for manufacturers and retailers to ensure compliance, maintain product quality, and meet consumer expectations.

Here a summary of most crucial tests regarding handles for cookware in this EU standards:

- Resistance to Burning: this test is performed to ensure that if a cookware handle is accidentally exposed to a direct flame source, it won't melt, lose pieces and put the user or the surface at risk of burns or surface damage.

- Heat Resistance Test: this test is performed to ensure that the cookware handle doesn't crack or break under exposure to prolonged heat by inserting the handle into the oven.

- Torque Resistance Test: the test involves the application of a torsion force on both sides of the handle, tightening the axis to ensure rotations don't damage the fastening system.

- Bending Strength Test: this test exposes the cookware handle to a force gradually released on the posterior part of the handle. The test stresses the resistance of the fixing system and the handle to ensure the user's safety.

- Fatigue Test: in this test the pot is filled in with an extra load and undergoes 15,000 cycles of up and down. The test wants to ensure that the cookware handle and its fixing system won’t have any permanent distortion or loosening since it stresses the cookware by overloading it with much more weight that what will be used in normal domestic cooking.

- Pull of Handle Assembly: the test is for assembled handles, which are pulled using a weight and must withstand a further dynamic impact without any damage.

These standards introduce significant changes to construction and performance requirements, emphasizing safety and durability.

Staying informed about the latest updates in European cookware standards is paramount for manufacturers and retailers alike.

US STANDARDS FOR POTS AND PANS

In the U.S.A., The Cookware and Bakeware Alliance (CBA), is a trade organization that sets voluntary standards for the industry’s products. Companies who adhere to CBA standards are encouraged to state this fact in advertising and promotional materials, as well as on product tags and labels.

The list of tests required by the CBA Engineering Standards has been recently updated too, with important revisions and a further harmonization with respect with the European ones.

The standard also includes a specific section dedicated to Handles & Fitting with tests focusing on handle assembly, how to measure handles and knob temperature and a specific guide for plastic cookware handle.

Among the tests included in the Engineering Standards Assembly Strength Test is particularly challenging in its HOT procedure since it requires the cookware to be loaded and to resist in a heated oven at 350 °F. This challenging test puts stress on the mechanical properties of the pot during weightlifting phase. It can be considered the test that determines the main difference between the two regulations.

F.B.M. YOUR COOKWARE HANDLE PARTNER FOR QUALITY AND SAFETY

Knowing the physical and mechanical properties of your cookware isn’t just a technical necessity—it’s a powerful way to demonstrate the quality, safety, and durability of your products to end users.

Among all the components, the handle plays a particularly important role. It’s the main point of contact between the user and the cookware. The sense of safety, comfort, and reliability that a handle provides is crucial—not only during daily use, but also at the point of sale, where it can strongly influence the buying decision.

At F.B.M., our mission goes beyond simply producing cookware handles and pans. As a global manufacturer known for Italian design, product innovation, and certified quality, we are proud to set high benchmarks in the industry.

We’re also deeply engaged in the international dialogue around cookware safety. F.B.M. actively collaborates with major industry associations such as CBA (Cookware and Bakeware Alliance) in the U.S. and FEC (Fédération Européenne des Fabricants d’Articles de Cuisine) in Europe. Our involvement includes extensive work on PFAS-related topics, sustainability regulations, and continuous improvements in product safety.

Driven by our commitment to excellence, F.B.M. invests in ongoing research, testing, and evaluation—ensuring our products not only meet but exceed international safety standards.

.png?width=285&height=276&name=Pasqua%20solidale%202024%20(1).png)

If you're looking for an in-depth overview of the main cookware safety standards—from testing procedures to specific certifications and how F.B.M. ensures compliance—download our free white paper.

It’s an essential guide for any brand or buyer that wants to stay informed and make confident, quality-driven decisions.

-Apr-03-2024-08-08-21-8075-AM.png?width=750&height=600&name=Image%20Credits%20SGS%20(1)-Apr-03-2024-08-08-21-8075-AM.png)