If you need to launch a large production run of kitchen pots or pans, make sure that your manufacturing partner has these features in place. They are essential to have successful production and to ensure that the end customer receives a quality product that meets requirements.

1. Quality and Service Standards Guaranteed Worldwide

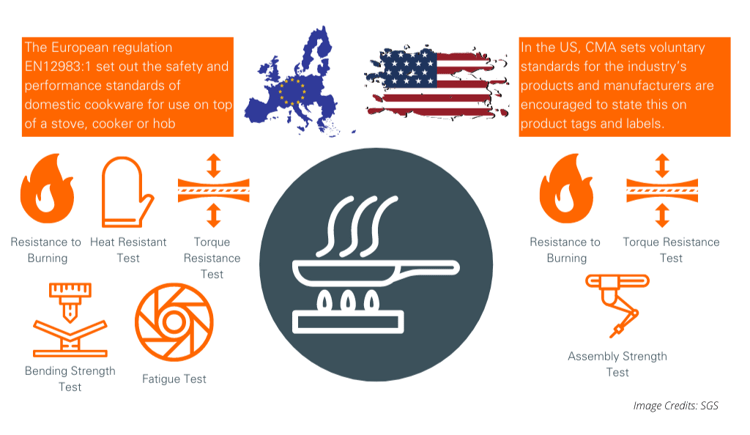

No matter where the cookware products are being produced, the items must meet the standards of the country where they will ultimately be sold. Cookware regulations exist to create a baseline quality measurement in the market.

Working with producers with multiple manufacturing facilities throughout the world is especially helpful for major brands or retailers with stores located in several countries. These customers regularly place orders from several regions worldwide and want to avoid selling products with quality variations from country to country.

2. International Support

infrastructure in place to provide support for all stages of production (manufacturing, packaging, shipping) in multiple languages for international deliveries to several countries. The production partner should also take the necessary steps to stay up to date about import country regulations to ensure shipments of pot and pan lids are in compliance.

3. Capacity and Production Speed

The cookware manufacturing partner obviously has the capacity and production speed for the first run of orders. What about capability to increase production as orders ramp up? How would your partner deal with a sudden influx of orders, requiring a rapid increase in production speed and warehouse storage capacity prior to shipping?

The manufacturer should have a detailed plan in place for these eventualities, not just the initial order. And that's not all. Over the past two years, customers have become even more attentive and responsive. They are much more sensitive to all possible forms of bonuses: in addition to the more classic solutions related to discounts and promotions in their loyalty paths, they are attentive to all forms of incentives and rewards.

This change of pace for brands engaged in loyaty pomotions and progamms translates into an increasing need to identify and distinguish the right partner who can guarantee large volumes in a short time and adequate marketing support.

4. Quality Guarantee AND INNOVATION SOURCE

A cookware partner with advanced, automated facilities in place will produce high quality cookware handles, while keeping waste from product defects to a minimum. We want to avoid working with production partners whose manufacturing techniques are focused on manual processes and low labor costs, since quality standards tend to be lower.

Automation ensures that the entire process is carried out in the same way (and to the same standard), regardless of the quantities being produced. This, in turn, translates into an advantage when it comes to large production runs or promotions. A company that chooses to invest in automation also reaps the advantages of investing in structured quality control processes. From the raw materials coming into the manufacturing facility to the final inspection before shipping, the quality control processes ensure that each product delivered to retailers (and ultimately to consumers) complies with the desired standards.

Moreover, a major partner must be able to be ahead of the times in order to be a unique and competitive in the market; the modern scenario is evolving and consumers are increasingly looking for products in line with their needs and expectations. Today more than ever there is a growing awareness of sustainability issues and an obsessive search for hygiene and safety in the kitchen.

5. Traceability of COOKWARE Products Through Production Lots

Errors can occur during the production process. It's essential to have an internal tracking system in place that can immediately identify any non-compliant production lots with a view to detecting the underlying causes and resolving them.

Ultimately, this practice will prevent multiple, subsequent non-compliant deliveries.

F.B.M. STANDS FOR AN ADDED VALUE IN QUALITY COOKWARE

F.B.M. srl is a leader in the field of cookware accessories, with several decades of experience in manufacturing and design to draw on when working with customers.

La Termoplastic F.B.M. srl offers outstanding design and certified quality in cookware handles and pans, working with customers from various locations worldwide. Our focus is on providing high-quality handles for cookware without sacrificing one ounce of creativity.

Contact us today if you have questions about our products or you would like to arrange a personal consultation.